Products

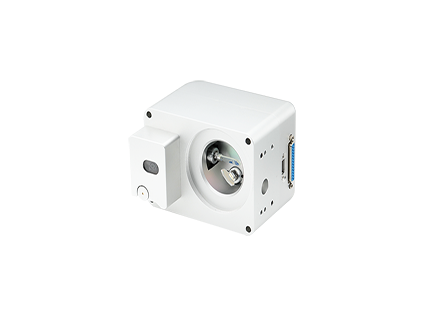

MC1603 Monitoring Scanning System

MC1603 High Speed Galvo Scanner motors are introduced from America.

It has good running stability, high positioning accuracy, fast marking speed, strong anti-interference ability, the overall performance of MC1603 has reached the international leading level in this field.

The advantages are as following:

■ Built-in 13 million pixel camera, positioning accuracy error is only 0.1mm.

■ With visual positioning module, it can automatically search for the target and calculate the marking position.

■ Adopted high-performance scanning motor which imported from the America and the international advanced photoelectric sensing technology.

■ Differential photoelectric sensor for accurate detection of motor rotor position, good linearity, lower drift, high resolution and repeat positioning.

■ Drives with advanced detection ability of position and speed, greatly improving the dynamic response performance and scanning speed of the whole system.

■ Design of overload, over-current and reverse connect protection, making the system running more reliable.

■ The whole system adopting the Optimization Designing of electromagnetic compatibility, with high signal-to-noise ratio and strong anti-interference ability.

■ Smaller scanner size, which meets the increasing industrial demands of higher precision and more compact systems.

■ MC1603 scan head can be integrated into different application systems easily. The housing is very strong and dustproof. Thus it can be used in the extremely bad environment.

|

Speed |

|

|

Marking Speed(1) |

4000mm/s |

|

Positioning Speed(1) |

4000mm/s |

|

Writing Speed(2) |

301cps |

|

Step Response Time(1% of full scale) |

370us |

|

Step Response Time(10% of full scale) |

630us |

|

Tracking Error Time |

≤202us |

|

Precision and Error |

|

|

Linearity |

99.9% |

|

Repeatability (RMS) |

<8μRad |

|

Gain Error |

<5mRad |

|

Zero Offset |

<5mRad |

|

Long-term Drift Over 8 Hours |

<0.5mRad |

|

Scale Drift |

<40PPM/℃ |

|

Zero Drift |

<15μRad./℃ |

|

Lens Damage Threshold |

|

|

K9 Matrix |

9.1J/cm^2 |

|

Si Matrix |

10J/cm^2 |

|

Wavelength(3) |

10600nm/1064nm/355nm |

|

Power and Signal |

|

|

Input Voltage |

±15VDC |

|

Rated Current |

2A |

|

Interface Signal |

XY2-100 |

|

Max Machinery Scan Angle(4) |

±11° |

|

Working Current, Temperature, Dimension |

|

|

Working Temperature |

0℃--45℃ |

|

Storage Temperature |

-10℃--60℃ |

|

Aperture |

10mm |

|

Galvanometer Scanner Dimension (LxWxH) |

134×96.5×120.6mm |

|

Galvanometer Scanner Weight |

≈0.9Kg |

|

Auto-focusing Control Parameters |

|

|

Measure Solution |

Laser Ranging |

|

Measure Resolution |

0.01mm |

|

Measure Accuracy |

±0.1mm |

|

Laser Wavelength |

620~690nm |

|

Single Measurement Time |

0.2s |

Note: The above data are tested after 30 min warm-up

(1) With F-theta objective, F=160mm, marking 2mm height single character

(2) With F-theta objective, F=160mm, marking 1mm height single character per second

(3) Special wavelength coating film can be customized

(4) If any special requirement, customization is available. Factory default value is ±11°